Most Cost-effective Metal core PCBs fabrication in China

Metal core printed circuit boards (MCPCB) are also referred to as thermal PCBs, insulated metallic substrate (IMS), insulated metal PCBs (IMPCB), thermal clad PCBs, and metal-clad PCBs. A metal core PCB incorporates a metal material as its base as opposed to the traditional FR4, for the heat spreader fragment of the board. Heat builds up due to some electronic components during the operation of the board. The purpose of the metal is to divert this heat away from critical board components and towards less crucial areas such as the metal heatsink backing or metallic core. Hence, these PCBs are apt for thermal management.

In a multilayer Medal core PCBs, the layers will be evenly distributed on each side of the metal core. For instance, in a 12-layer board, the metal core will be at the center with 6 layers on the top and 6 layers at the bottom.

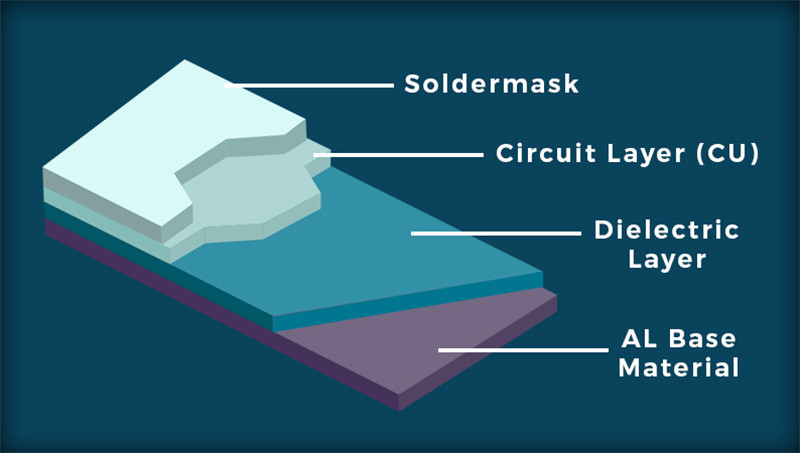

Medal core PCBs are made up of thermal insulating layers, metal plates, and metal copper foil.The basic structure of Medal core PCBs comprises of the following:

● Solder Mask

● Circuit Layer

● Copper layer – 1oz. to 6oz. (most commonly used 1oz. to 2oz.)

● Dielectric Layer

● Metal Core Layer

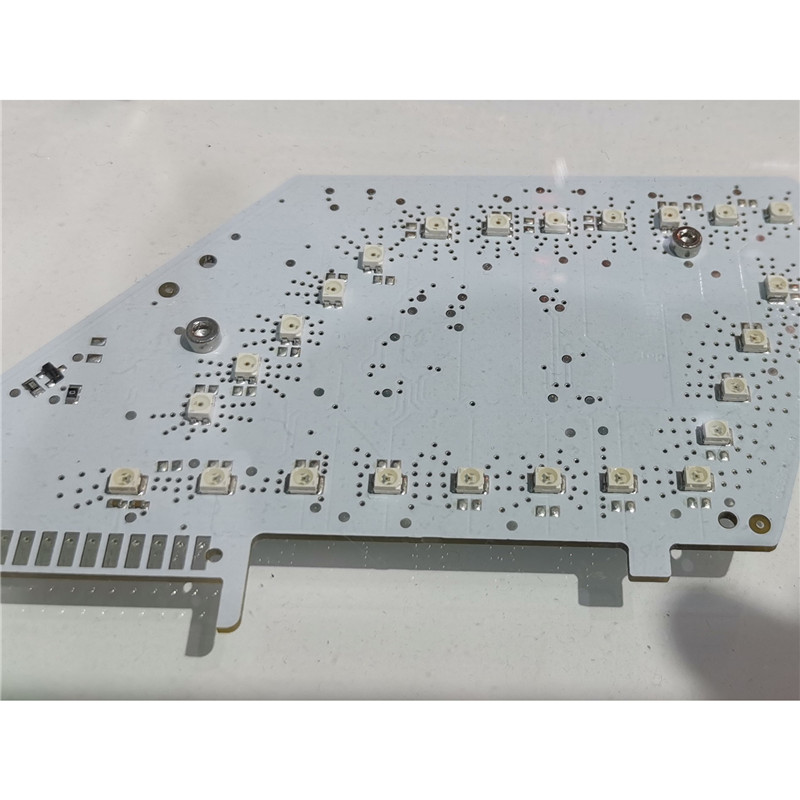

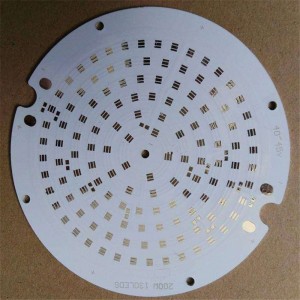

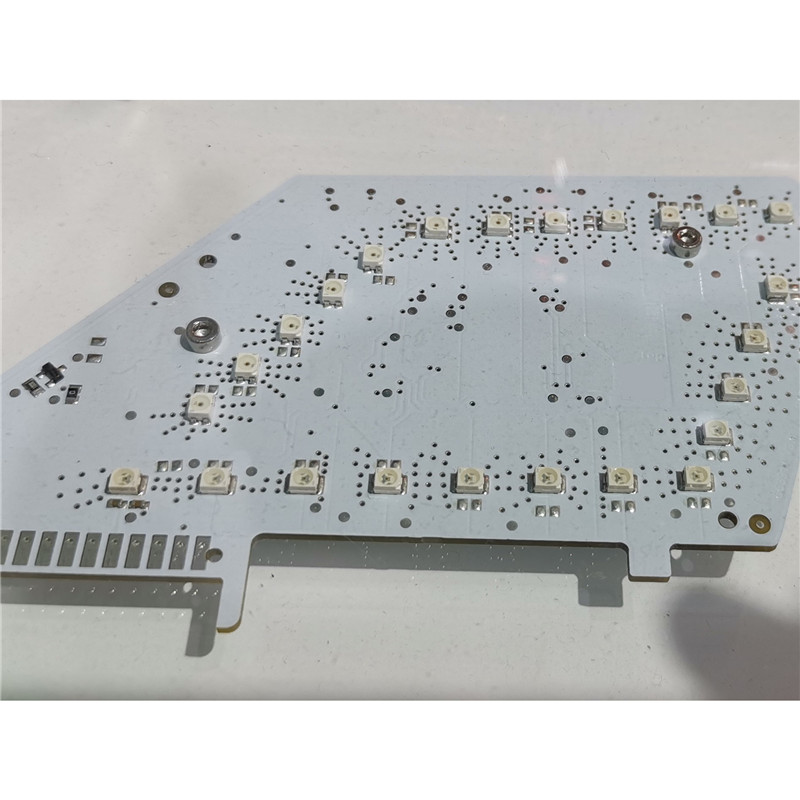

Metal core circuit boards are an excellent alternative to standard circuit boards, if the circuit boards are exposed to large mechanical loads, or a high level of dimensional stability is required, or high temperatures must be conducted away from power components or LEDs.

Aluminum substrate – The aluminum printed circuit boards offer good heat dissipation and heat transferring ability. Since they are light in weight, the aluminum core PCBs find their purpose in LED lighting, audio frequency apparatus, and communication electronic equipment.

Copper substrate (copper core or heavy copper) – The copper core boards feature better performance than aluminum. However aluminum is mostly chosen for less cost and copper cores being heavier and involving a tough machining process.

Metal core PCBs are most widely found in LED technologies. Some of the popular applications are:

● LED (Backlight Unit, General Lighting)

● Automotive

● Moto Drives

● Solid-State Relays

● Power Converters

● Electric/Hybrid Motor Control

● Solar Panels

● Motion Control

● Photovoltaic

● Heat Spreaders

● Heat Sinks

Benefit from our many years of experience with Insulated Metal Substrate PCBs. the thermal conductivity assisted by the aluminum core in the circuit boards manufactured by PCB ShinTech enables higher packing density, more stable operating parameters, higher operational safety and a reduced failure rate. An Aluminum Base PCB from us will easily help you control the heat that is generated by the devices you expected them for, reduce costs from space saving.

PCB ShinTech has been providing quality high quality Aluminum core, Copper core and Steel core PCBs to a variety of industries since 2003. All of our metal core printed circuit boards are tested and certified with ISO9001, TS16949 and UL. Contact Us»

Inclusive

● Alu core 1.5mm, 35µm Cu

● 2.0 W/mK Thermal conductivity

● insulation 100µm thickness

● Surface HAL lead-free

● 1x solder-stop white

● Milling inner, outer

● V-Scoring (clean & simple)

● E-Test

Please refer to the Full PCB manufacturing Capabilities Sheet ».

High quality Metal Core (Aluminum, Copper and steel) Printed Circuit Boards are available upon request.

Send your inquiry or quote request to us at sales@pcbshintech.com to get connected to one of our sales representatives who have the industry experience to help you get your idea to market.