Pcb Fabrication - Manufacturers, Suppliers, Factory from China

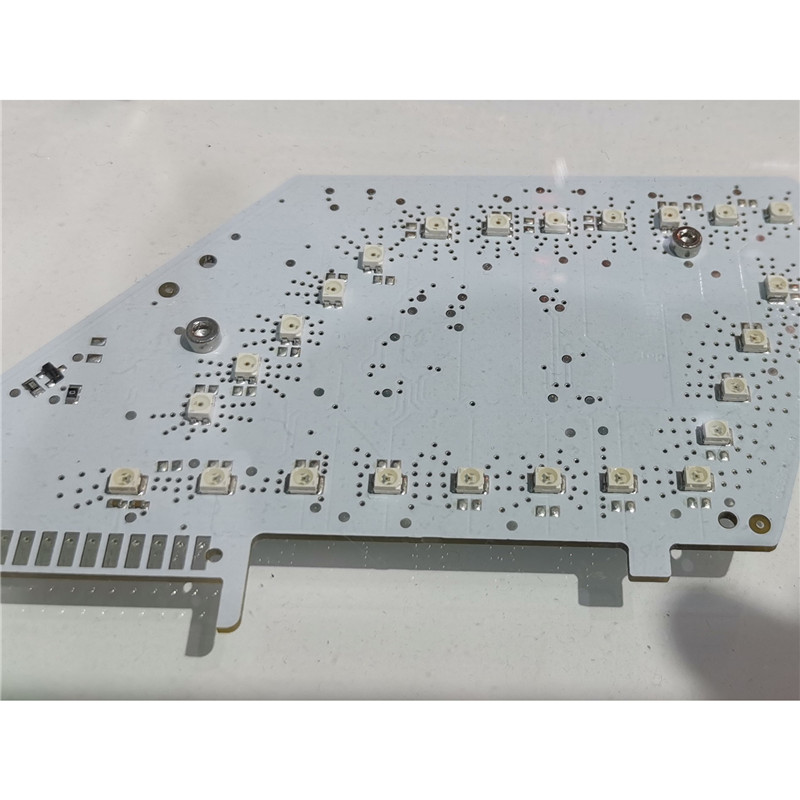

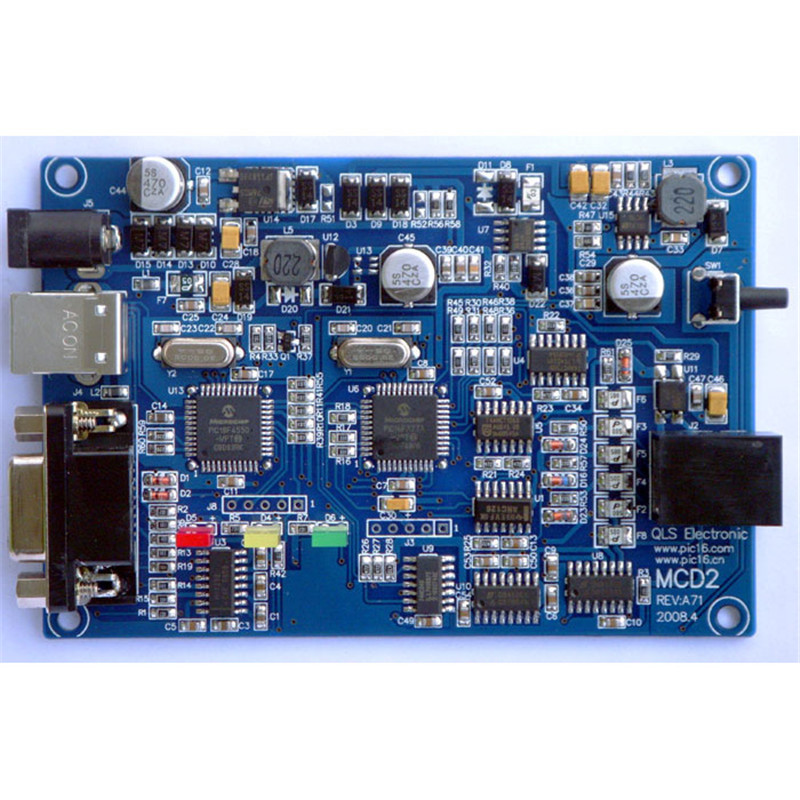

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for Pcb Fabrication, Low Volume Pcb , Chimney Pcb , On Site Pcb Facilities ,Automotive Circuit Board . Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us! The product will supply to all over the world, such as Europe, America, Australia,Doha, Denver,Jersey, Ghana.Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

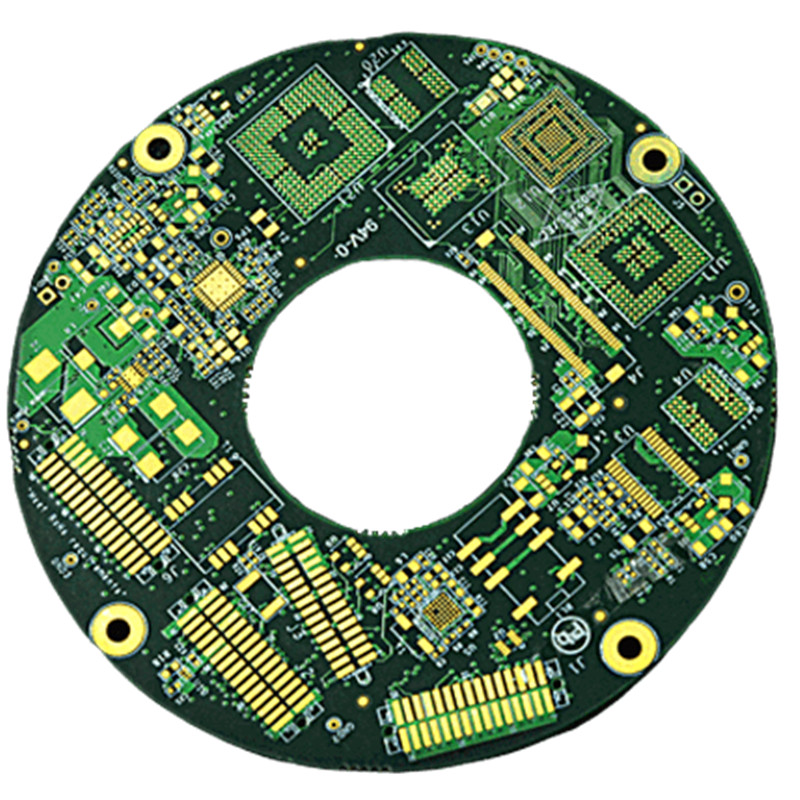

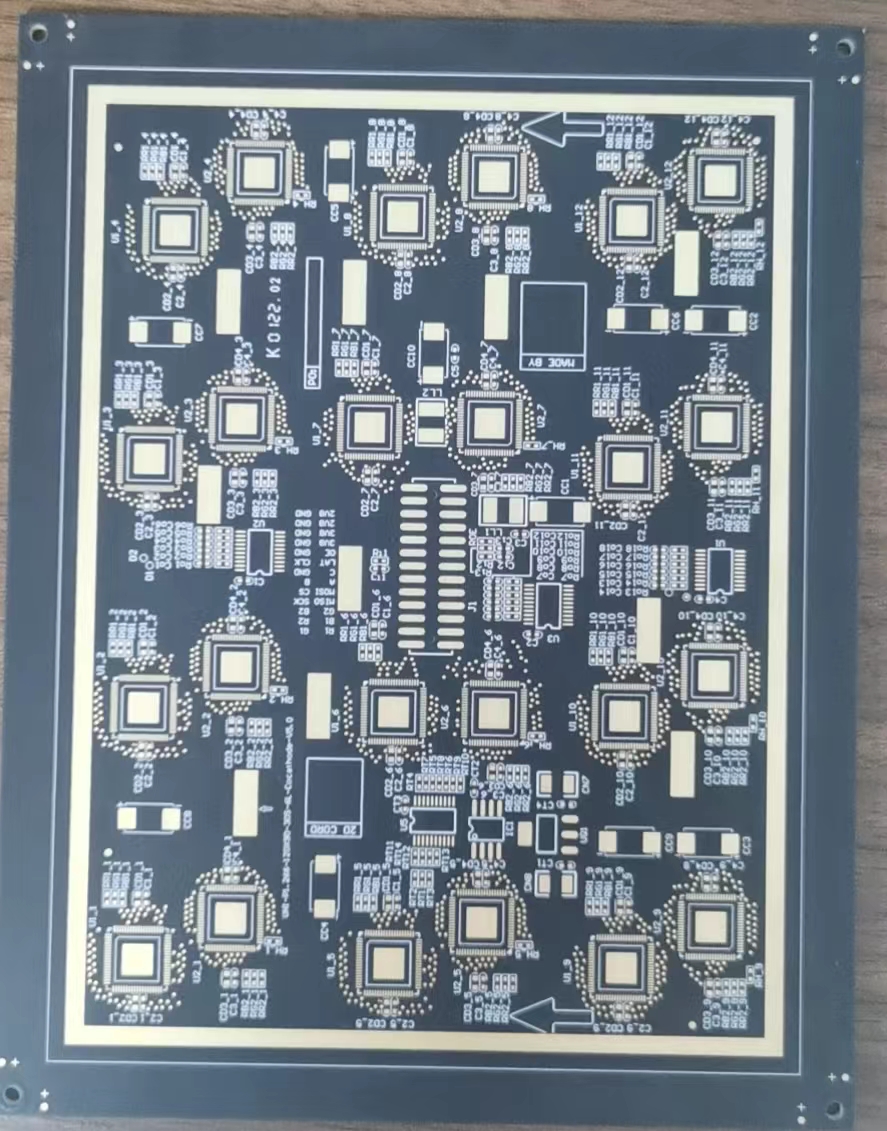

Related Products