Manufacturing Companies for Uas Board Assembly - Leading PCB Assembly Manufacturer: fully turnkey and kitted turnkey services – PCBShinTech

Manufacturing Companies for Uas Board Assembly - Leading PCB Assembly Manufacturer: fully turnkey and kitted turnkey services – PCBShinTech Detail:

Get a PCB Manufacturing Quote

Get an Assembly Quote

Full Capabilities List

[PDF] Download Full Capabilities Sheet »

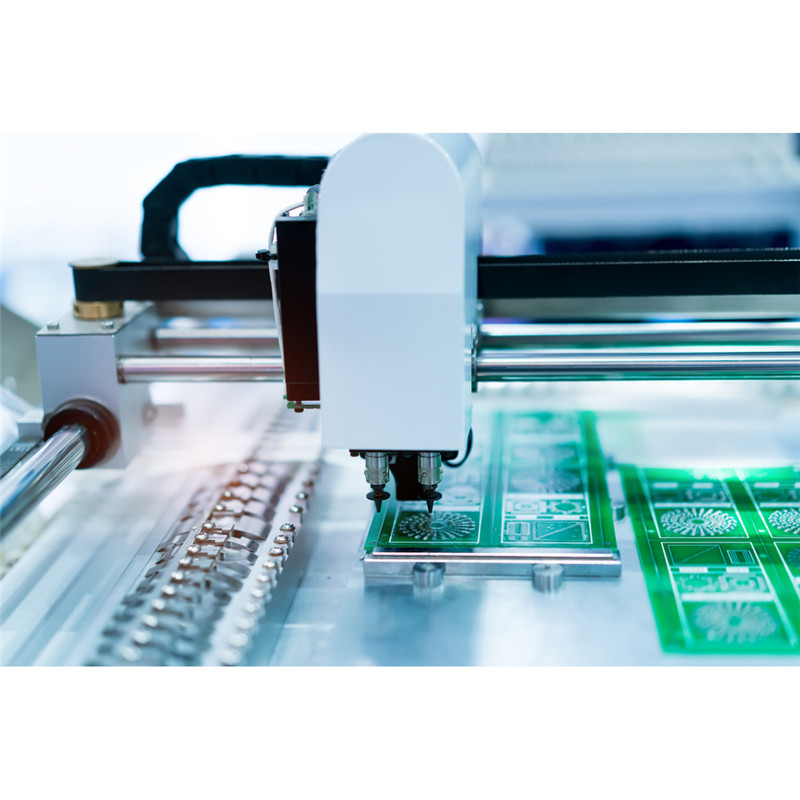

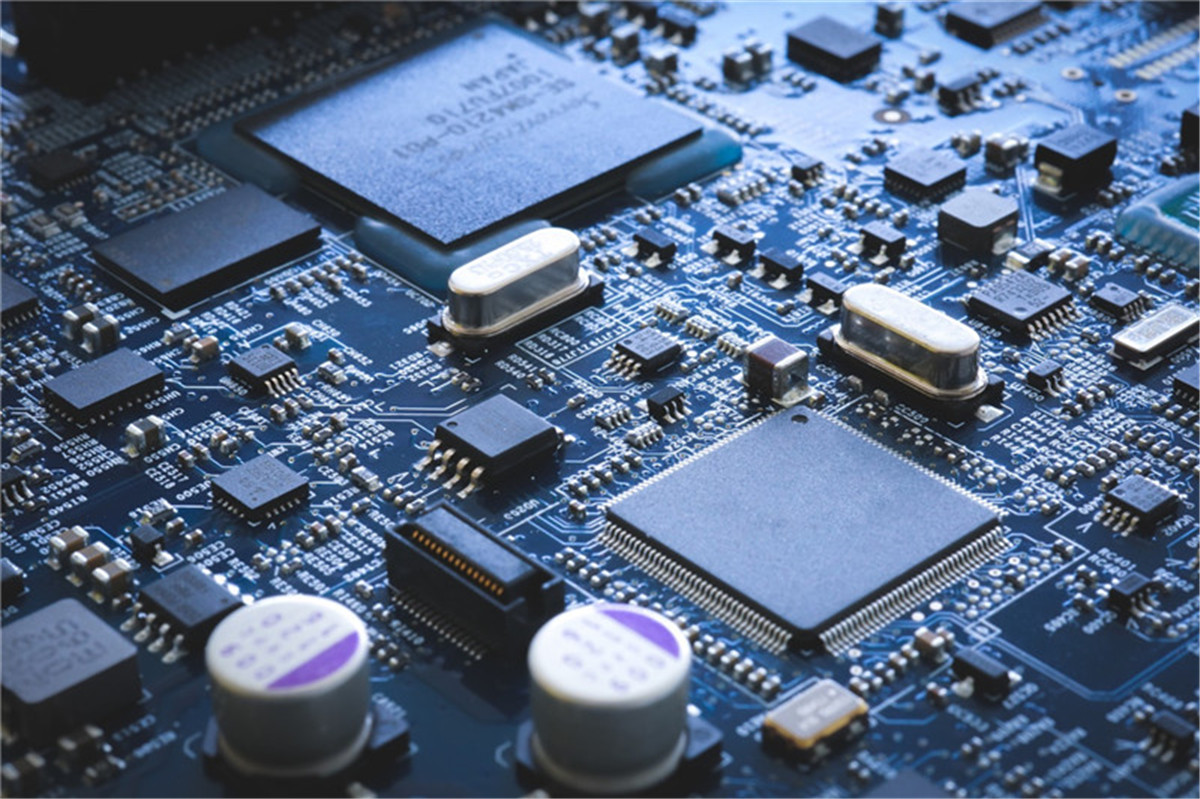

PCB ShinTech is one of the well-known PCB Assembly companies in China, with 15+ years’ experience supplying and assembling circuit boards. Our state-of-the-art facility uses the latest SMT and Through-hole equipment to manufacture quality and reliable products in a timely fashion for our customers.

services

FULLY TURNKEY AND PARTIAL SERVICES

Fully turnkey PCB assembly service

With full turnkey assembly, we handle all aspects of the assembly project: manufacturing bare circuit boards, sourcing materials and components, welding, assembly, coordinating logistics with assembly factory on lead times, potential overages/substitutions, etc., inspection and tests, and delivery of products to customer.

Kitted turnkey/partial PCB assembly service

Partial/kitted turnkey allows customers to take control of one or more processes listed above. Most often for partial turnkey services, the customer ships us the components (or partial consignment if not all components are supplied) and we take care of the rest.

For those who know exactly what they want in their PCBs, but perhaps don’t have the time or equipment to assemble, kitted printed circuit board assembly is a perfect choice. You can purchase partial or all of the components and parts you need, and we will help you to assemble the PCBs. This can help you have better control of production costs and know what to expect with the completed circuit boards.

Whichever turnkey service you choose, we ensure that bare PCBs are manufactured to specification, assembled efficiently and meticulously tested. With highly automated processes, we’re capable of getting your project completed efficiently from prototypes to large volume production.

LEAD TIME

Our lead time for turkey PCB assembly orders is usually around 2-4 weeks, PCB manufacturing, component sourcing, and assembly will be finished within the lead time. For kitted PCBA service, 3-7 days can be expected if bare boards, components and other parts are ready, and can be as short as 1-3 days for prototypes or quickturn.

1-3 work days

● 10 pcs Maximum

3-7 work days

● 500 pcs Maximum

7-28 work days

● Above 500 pcs

Scheduled Shipments also Available for High Volume Production

The specific lead time is depending on your product specifications, quantity and if it is a time of peak purchasing. Please to contact your sales representative for details.

Quote

Please combine the following files into a single ZIP file and contact us at sales@pcbshintech.com for quotation:

1. PCB Design File. Please include all Gerbers (at minimum we require copper layer(s), solder paste layers, and silkscreen layers).

2. Pick and Place (Centroid). Information should include component location, rotations, and reference designators.

3. Bill of Materials (BOM). Information provided must be in machine readable format (Excelleon preferred). Your scrubbed BOM should include:

● Quantity of each part.

● Reference designator – alphanumeric code that specifies the location of a component.

● Vendor and/or MFG Part Number (Digi-Key, Mouser, Etc.)

● Part description

● Package description (QFN32, SOIC, 0805, etc. package is very helpful but not required).

● Type (SMT, Thru-Hole, Fine-pitch, BGA, etc.).

● For partial assembly, please notate in BOM, “Do Not Install” or “Do Not Load” for components that will not be placed.

Download our file requirements:

PCB Assembly File Requirements

Sample Bill of Materials (BOM) for Assembly Quote

Assembly Capabilities

PCB assembly capabilities of PCB ShinTech include Surface Mount Technology (SMT), Thru-hole, and mixed technology (SMT with Thru-hole) for single and double-sided placement. Passive Components as small as 01005 package, Ball Grid Arrays (BGA) as small as .35mm pitch with X-Ray inspected placements, and more:

SMT Assembly Capabilities

● Passive Down to 01005 size

● Ball Grid Array (BGA)

● Ultra-Fine Ball Grid Array (uBGA)

● Quad Flat Pack No-Lead (QFN)

● Quad Flat Package (QFP)

● Plastic Leaded Chip Carrier (PLCC)

● SOIC

● Package-On-Package (PoP)

● Small Chip Packages (Pitch of 0.2 mm)

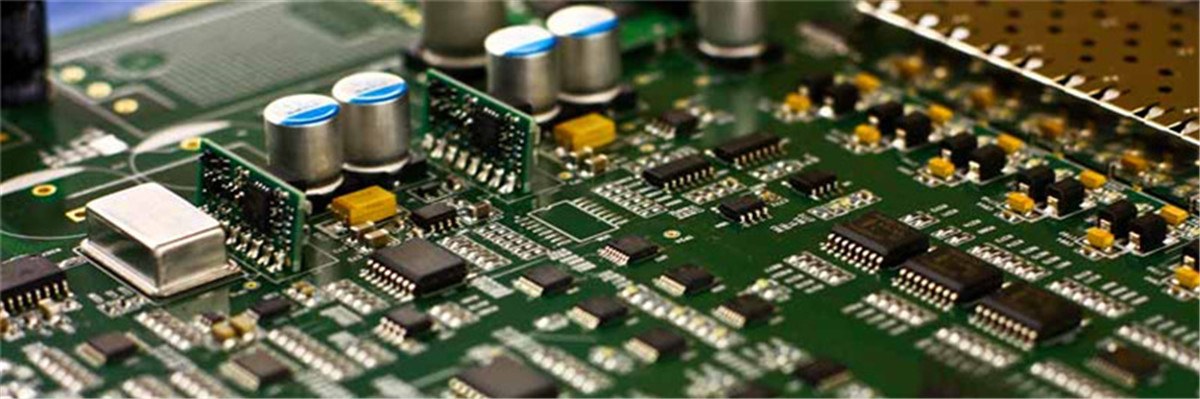

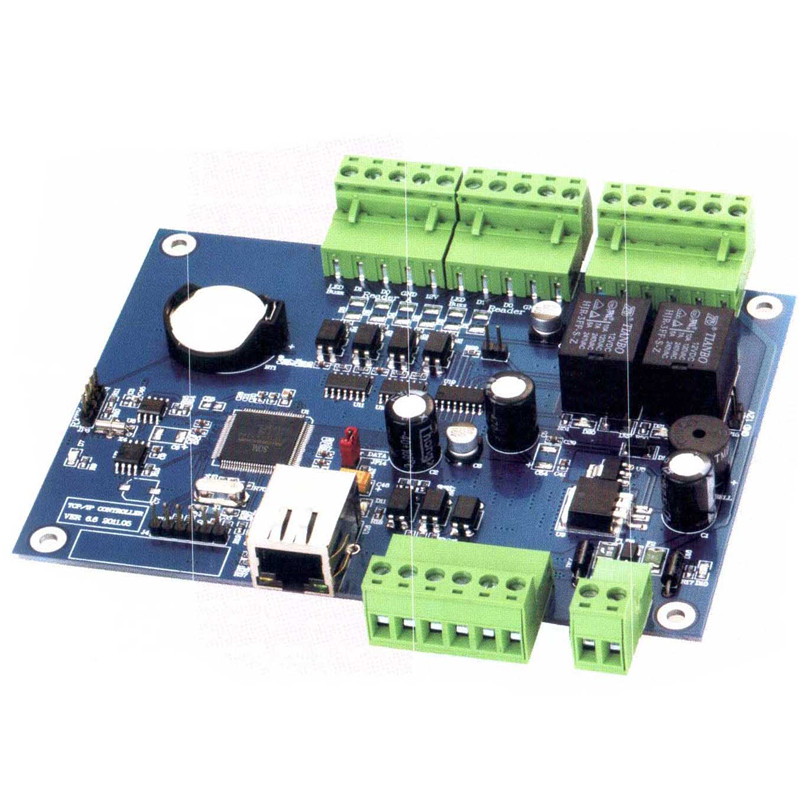

Through-Hole Assembly

● Automated and Manual Through-Hole Assembly

● Thru-hole technology assembly is used to create stronger connections compared to surface mount technology due to the leads running all the way through the circuit board. This assembly type is often chosen for testing and prototyping that require manual component modifications and for applications that require high reliability.

● Through-hole mounting techniques are now usually reserved for bulkier or heavier components such as electrolytic capacitors or electromechanical relays that require great strength in support.

BGA Assembly Capabilities

● State-of-the-art automatic placement of Ceramic BGA, Plastic BGA, MBGA

● Verification of BGA’s using real-time HD X-ray inspection system to eliminate assembly defects and soldering problems, such as loose soldering, cold soldering, solder balls and paste bridging.

● Removing & Replacing BGA’s & MBGA’s, minimum 0.35mm pitch, large BGA’s (up to 45mm), BGA Rework and Reballing.

Mixed Assembly Advantages

● Mixed Assembly – Through-Hole, SMT and BGA components are housed on the PCB. Single or double-sided mixed technology, SMT (Surface Mount) and through-hole for PCB assembly. Single or double-sided BGA and micro-BGA installation and rework with 100% X-ray inspection.

● Option for components that have no surface mount configuration.

No solder paste used. Custom assembly process to suit the specific requirements of our customers.

Click here for the Full PCBA Capabilities List of PCB ShinTech

Quality Control

We employ thorough quality control processes.

● All bare PCBs will be electrically tested as a standard procedure.

● Visible joints will be inspected by eye or AOI (automated optical inspection).

● First-off assemblies are checked off-line by experienced quality inspectors.

● When required, in-house X-ray inspection of BGA (Ball Grid Array) placements is a standard procedure.

PCB Assembly Facilities and Equipment

PCB ShinTech has 15 SMT lines, 3 through-hole lines, 3 final assembly lines in-house. To achieve exceptional quality performance from PCB assembly, we continuously invest in latest equipment, update expertise among operators which assure of fine pitch BGA’s and 01005 packages as well as all commonly available parts placing. On the rare occasions we do experience difficulty with a parts placement, PCB ShinTech is equipped in-house to professionally rework every type of component.

PCB Assembly Equipment List

|

Manufacturer |

Model |

Process |

| Comiton | MTT-5B-S5 | Conveyor |

| GKG | G5 | Solderpaste Printer |

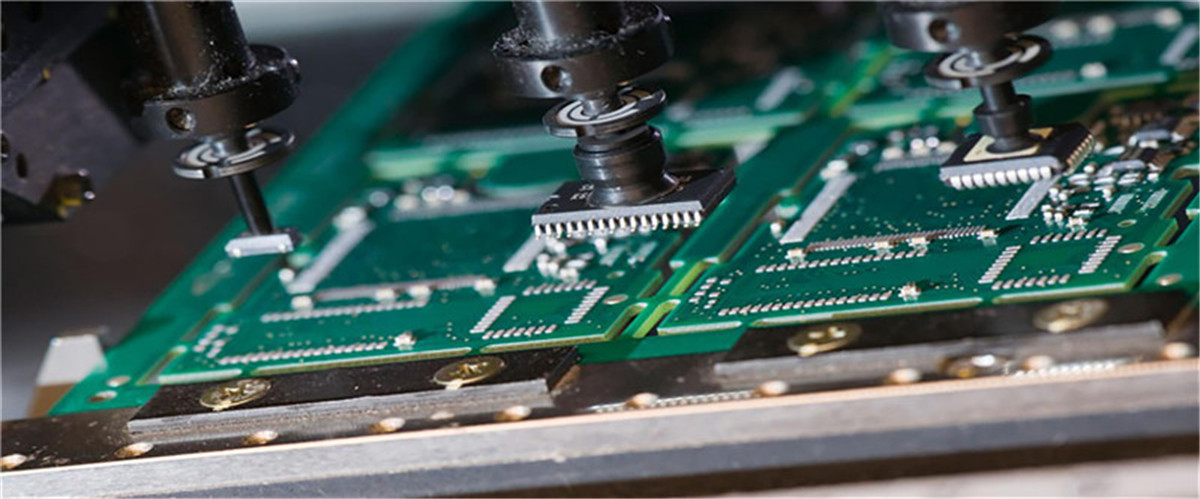

| YAMAHA | YS24 | Pick and Place |

| YAMAHA | YS100 | Pick and Place |

| ANTOM | SOLSYS-8310IRTP | Reflow Oven |

| JT | NS-800 | Reflow Oven |

| OMRON | VT-RNS-ptH-M | AOI |

| Qijia | QJCD-5T | Oven |

| Suneast | SST-350 | Wave Solder |

| ERSA | VERSAFLOW-335 | Selective Solder |

| Glenbrook Technologies, Inc. | CMX002 | X-Ray |

PCB & Electronic Assembly Process

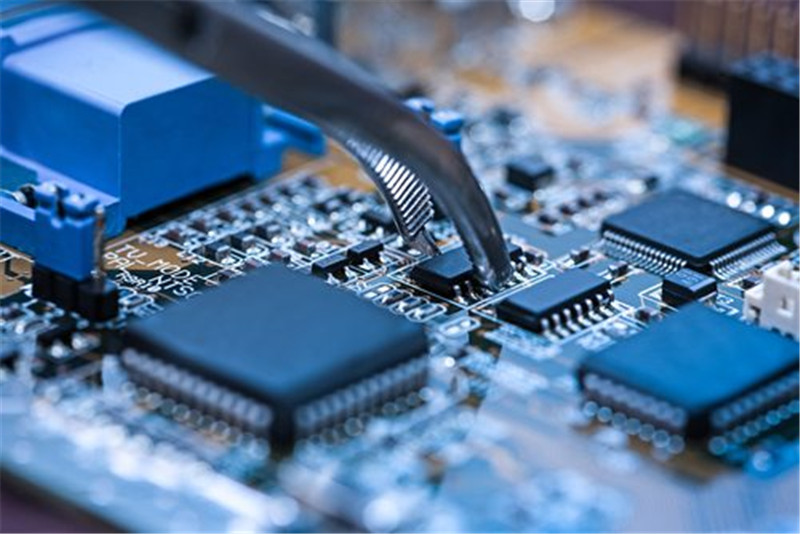

As far as possible, we will use automated processes to place components on to your bare PCB, making use of your pick & place CAD data. Component positioning, orientation and solder quality will normally be verified using Automatic Optical Inspection.

Very small batches may be placed by hand and inspected by eye. All soldering will be to Class 1 standards. If you require Class 2 or Class 3, please ask us to quote.

Remember to allow time in addition to your quoted assembly time to enable us to kit your BOM. We will advise the increase in delivery time in our quote.

Send your inquiry or quote request to us at sales@pcbshintech.com to get connected to one of our sales representatives who have the industry experience to help you get your idea to market.

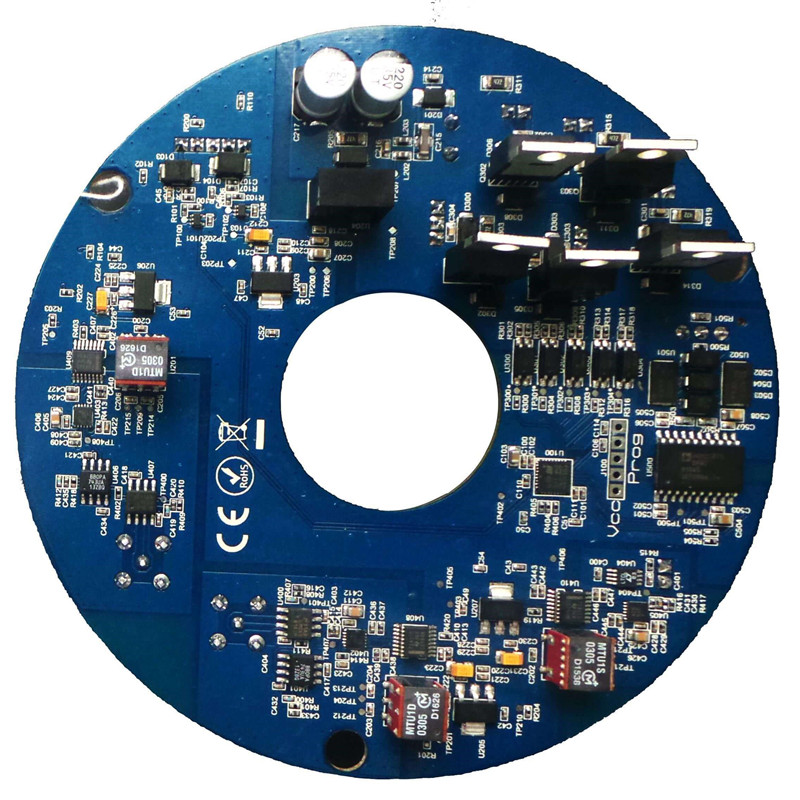

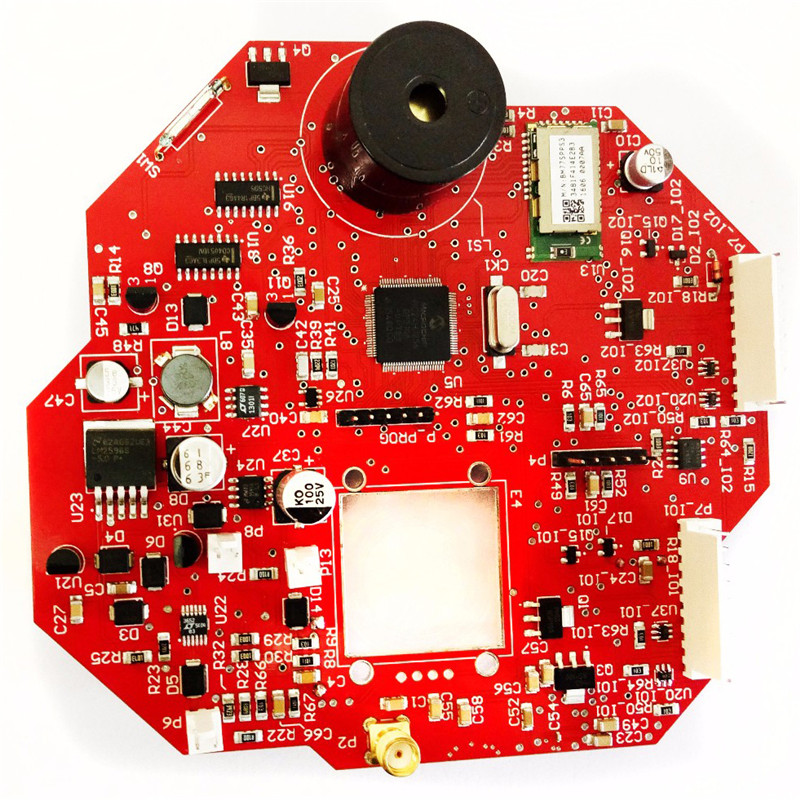

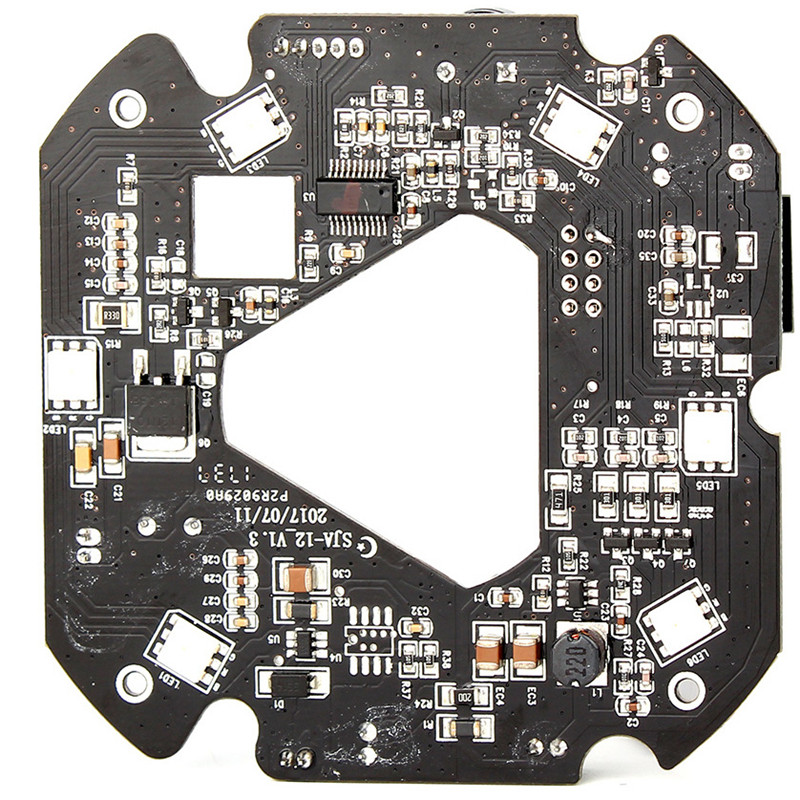

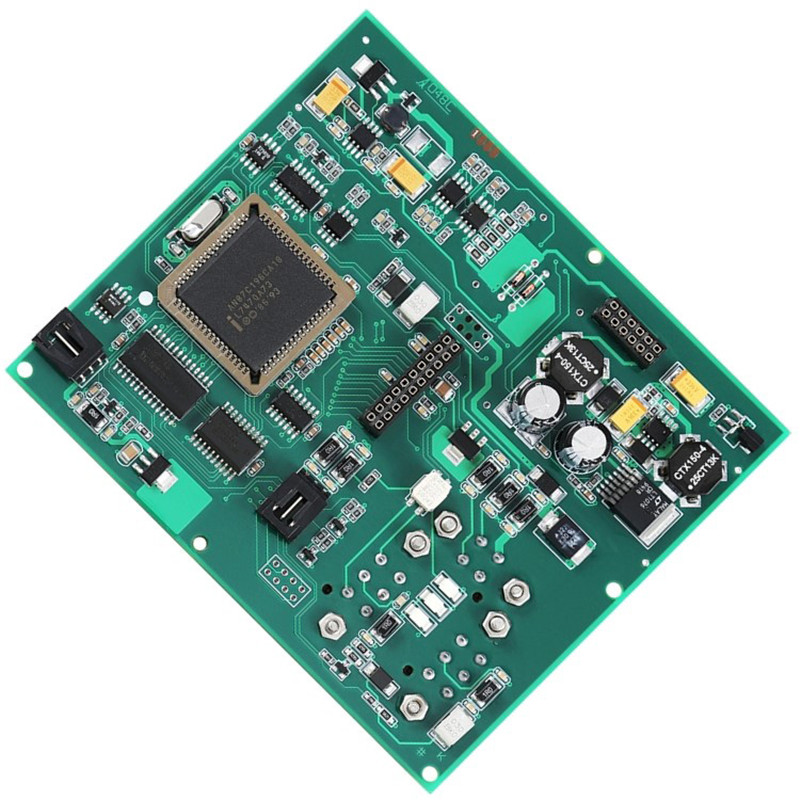

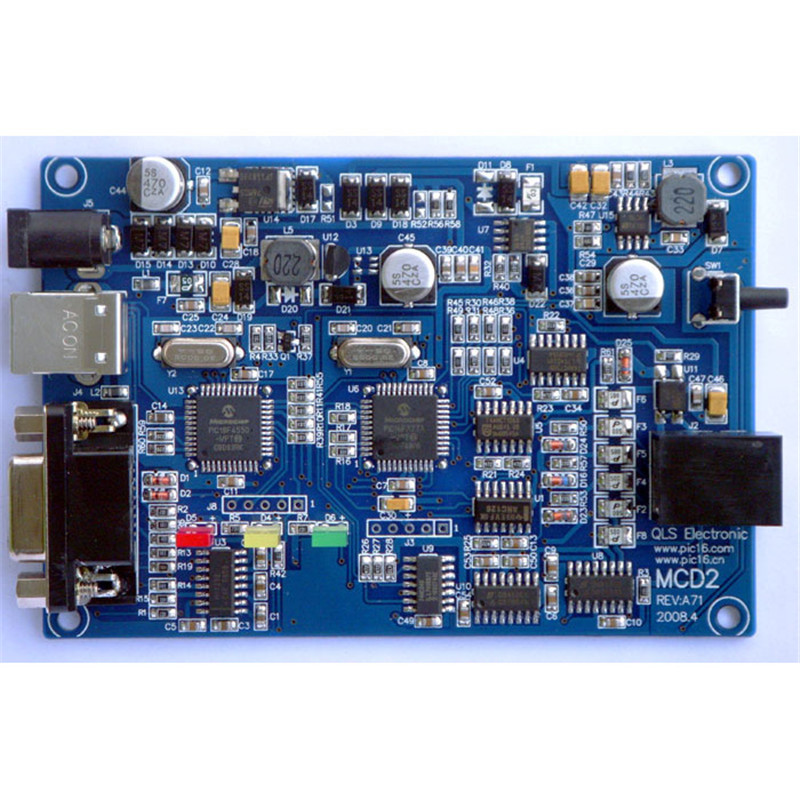

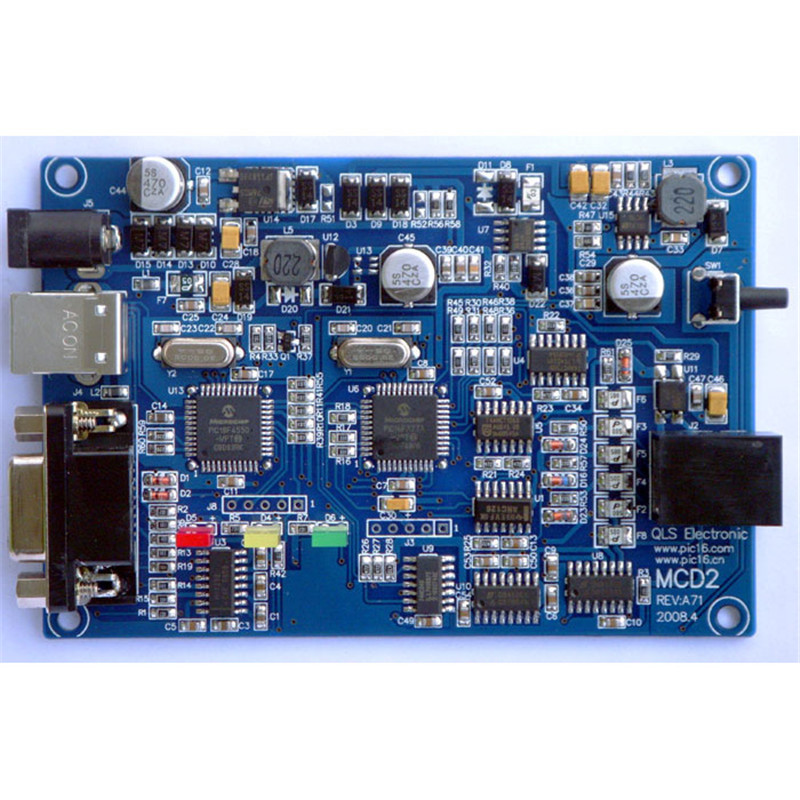

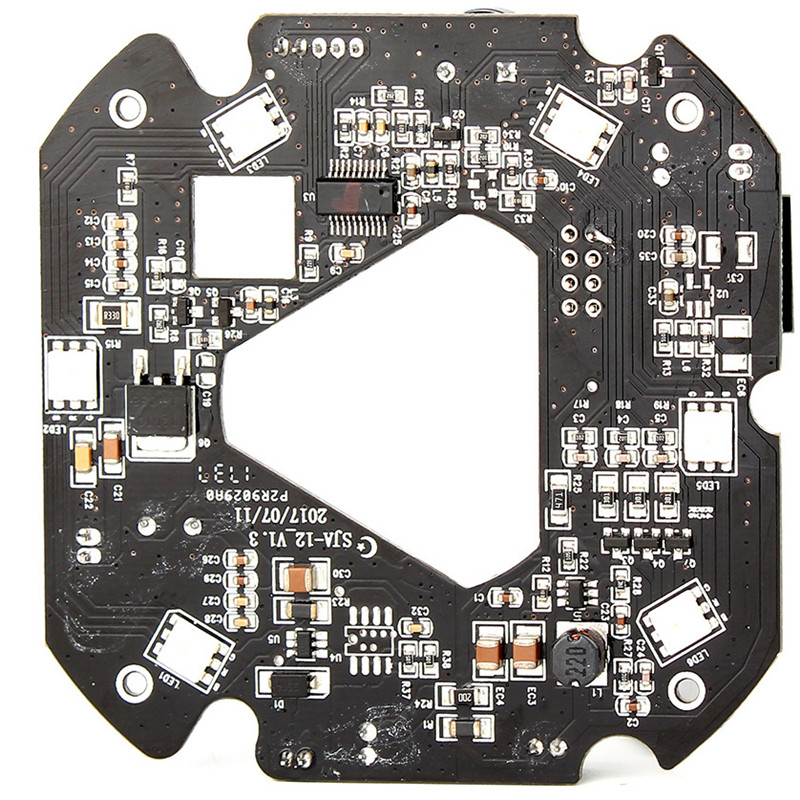

Product detail pictures:

Related Product Guide:

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Manufacturing Companies for Uas Board Assembly - Leading PCB Assembly Manufacturer: fully turnkey and kitted turnkey services – PCBShinTech , The product will supply to all over the world, such as: Sweden, Finland, San Diego, We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.