China Manufacturer for Circuit Board Solution - Excellent Custom high frequency RF/Microwave PCBs Manufacturing Service – PCBShinTech

China Manufacturer for Circuit Board Solution - Excellent Custom high frequency RF/Microwave PCBs Manufacturing Service – PCBShinTech Detail:

RF PCB and microwave PCB are a type of printed circuit boards which carry the RF or microwave signal. So, RF PCBs and microwave circuit boards usually work at frequency range from megahertz to gigahertz making it ideally suited for high-speed designs, as well as radio frequency (RF), microwave and mobile applications. These higher transmission frequencies can also provide the faster signal flow rates that are a necessity in today’s increasingly complex electronic switches and other components.

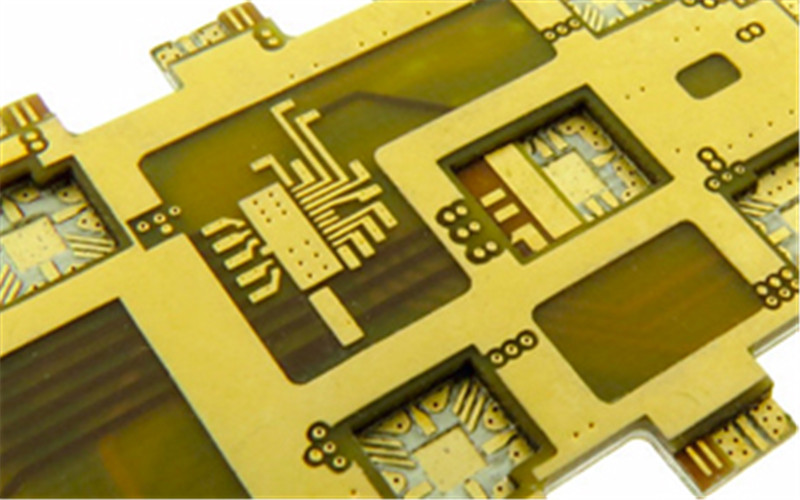

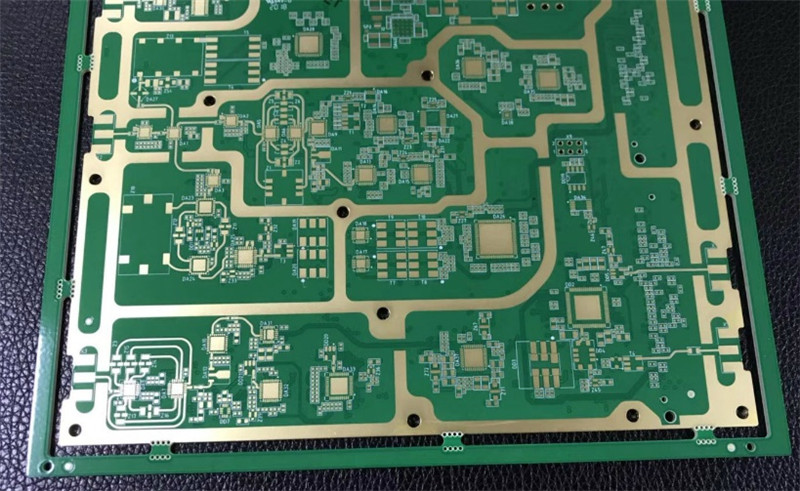

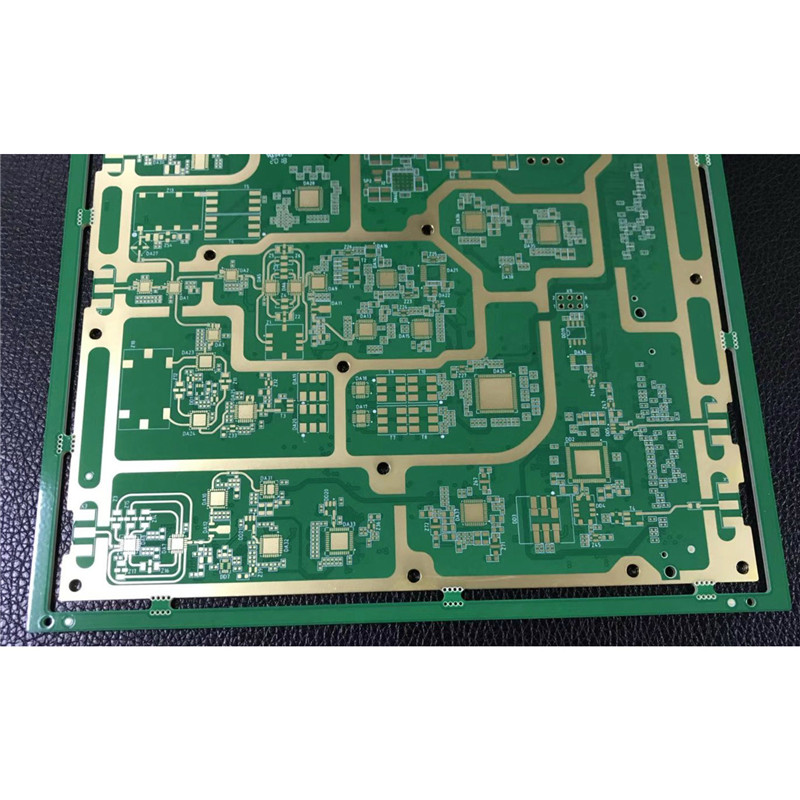

RF circuit board and microwave PCB board can work on high Frequencies.They have a stable structure which allows them to work in high temperature environment. High frequency PCBs have a stable dielectric constant and a low loss tangent. So, the signal travels through them with minimum impedance. RF / microwave circuit boards are cost-effective for having smaller stack up boards. RF / microwave boards show optimal performance while they make fine pitch components be easily assembled onto the boards with complex layouts.

High frequency circuits have more stringent requirements in the material, signal speed, signal loss, tolerances, and circuit design which your normal PCB suppliers may not be able to handle. PCB ShinTech have highly sophisticated production facilities and a dedicated manufacturing and service team. We can be your go to source for high frequency PCBs with high-frequency laminates, tight lead times, strict quality controls to ensure proper operation.

Special materials are required to achieve the high frequency provided by RF/ Microwave printed circuit board – any changes in the Er value of these materials can affect the impedance of the board. The material PCB ShinTech use in the manufacturing of RF PCBs and microwave PCBs mostly depends on the application. So, you can use the following chart to identify the suitable high frequency PCB material for your desired application. Contact Us»

| Applications | Materials | Characteristics |

| Consumer Electronics | RO3006 | Cost-effective with reliable thermal and electrical characteristics |

| RO3010 | ||

| RO4835 | ||

| Military/Aerospace | RT/ Duroid | Best thermal and electrical performance. Excellent environmental durability. |

| RO4000 | ||

| Medical | RO4350B | A wider range of properties which are suited for various types of medical devices. |

| Industrial | RO4835 | Excellent durability. Improved environmental resistance. |

| XT/ Duroid | ||

| RO4350B |

Click here to Order or Get a Quote

Inclusive

● Dielectric Constant 3.50

● Coefficient of Thermal Expansion 46 ppm/°C

● Dimensional Stability <0.5mm/m

● Moisture Absorption 0.06 %

● Thermal conductivity 0.73 W/m/°K

● Electrical Strength 30.2 KV/mm

● Frequency 104 – 108 Hz

Please refer to the Full PCB manufacturing Capabilities Sheet ».

Send your inquiry or quote request to us at sales@pcbshintech.com to get connected to one of our sales representatives who have the industry experience to help you get your idea to market.

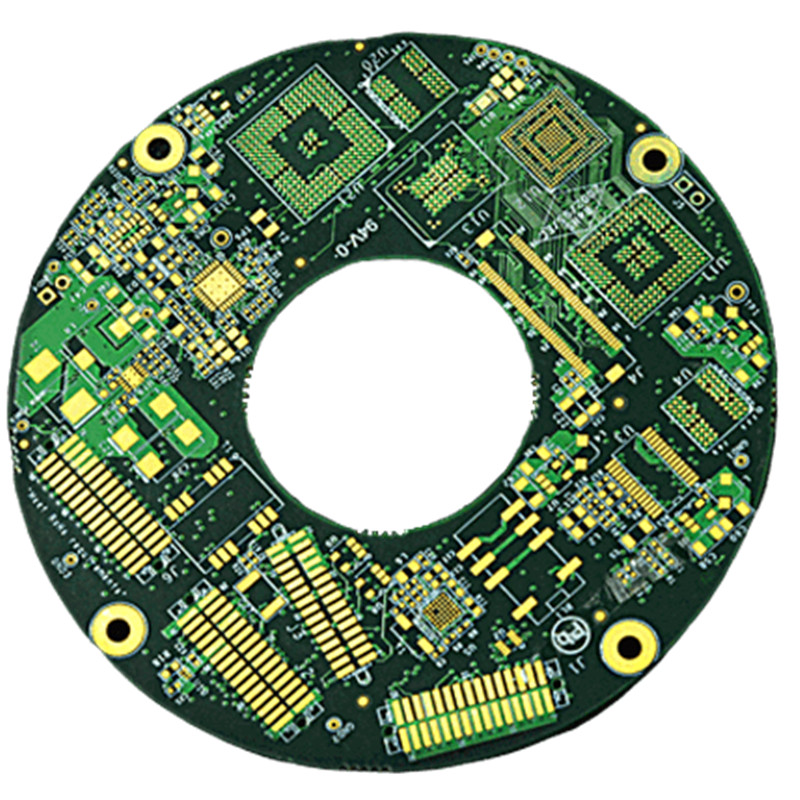

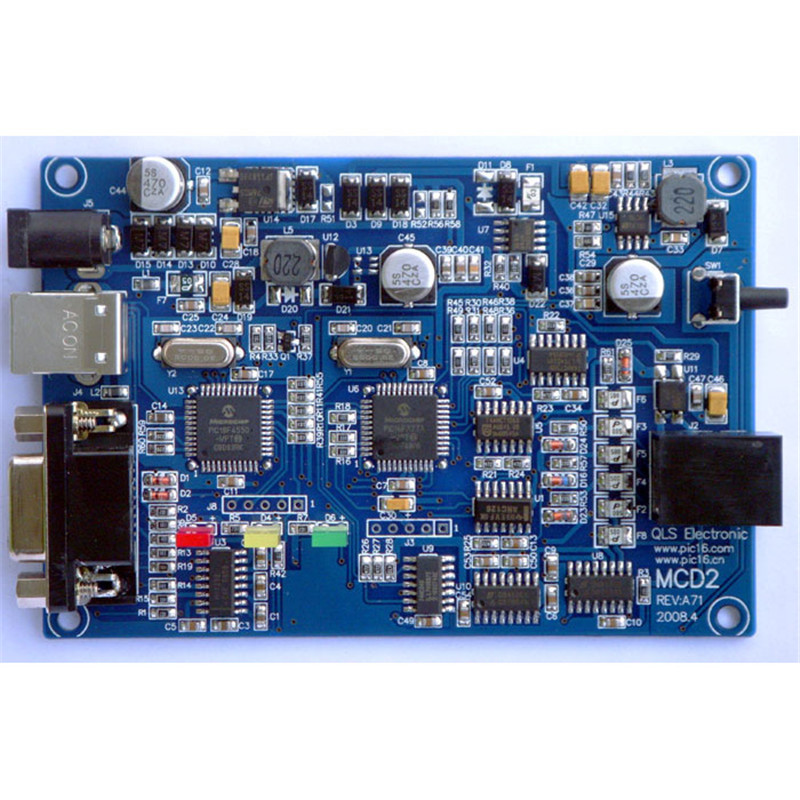

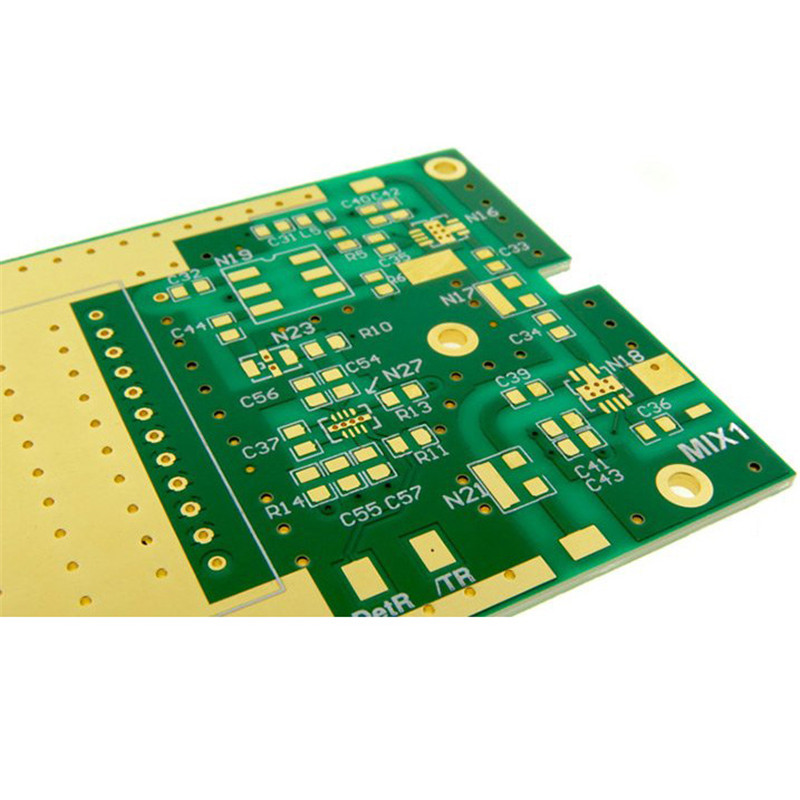

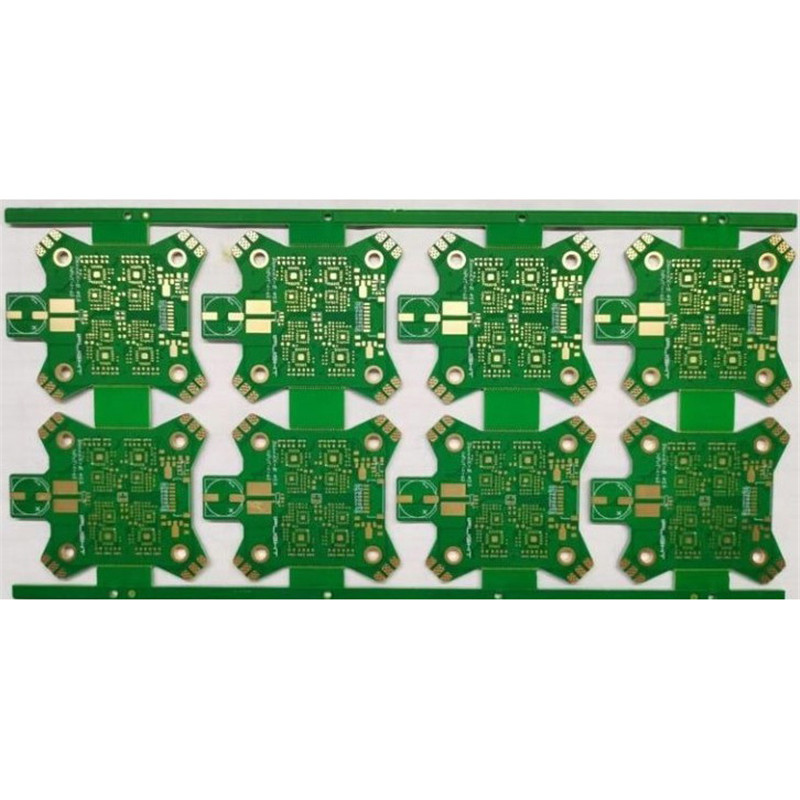

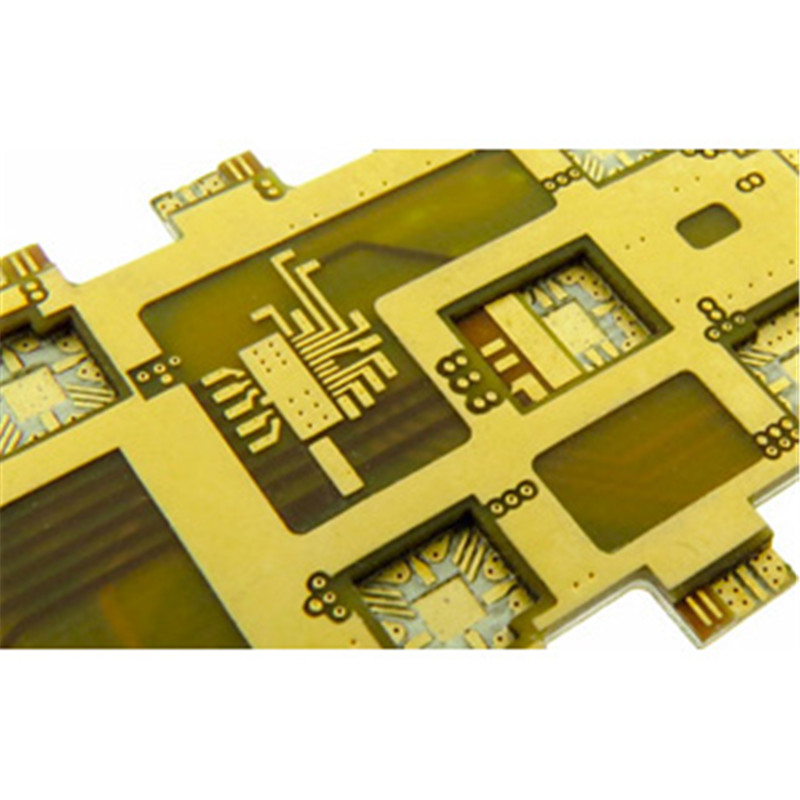

Product detail pictures:

Related Product Guide:

Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for China Manufacturer for Circuit Board Solution - Excellent Custom high frequency RF/Microwave PCBs Manufacturing Service – PCBShinTech , The product will supply to all over the world, such as: Kuwait, UAE, kazan, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for you in China. Of course, other services, like consulting, can be offered too.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!